GF 2

A well balanced sickle bar with quick coupling for other implements

|

The Grillo GF2 is a perfectly balanced sickle bar. Engine and P.T.O. are positioned in such way that thanks to the ground clearance obtained it is ideal for cutting on slopes. The centre of gravity was designed to ensure manoeuvrability and safety in the most demanding working conditions. The three gears can all be used whilst mowing. The Grillo GF2 is fitted with an active cone clutch, a device which ensures remarkably the operator’s safety. The wide choice of cutter bars ensures meets the requirements of all operators. The numerous accessory range attached by means of a quick coupling, make the GF2 a multi-purpose machine! |

|

The standard cutter bar is the single blade PRO CUTTER BAR, 117 cm width and crank action. |

|

|

The 117 cm double blade central cutter bar with its action has a mulching cut mode and is fitted with two blades moving in opposite direction. This “scissor like” cutting action considerably reduces the vibrations on the handlebar when mowing, ensuring an optimal quality cut in all conditions. |

|

The normal central cutter bar of 110 cm has a crank action and quick coupling. It’s the specific cutter bar for mowing and obtaining grass for animal feed. The crank mechanism was built with premium steel types and is fitted with grease nipples on all articulating parts. The floating grass disperser is mounted on anti-vibration rubbers with a special profile to dispel the grass in the most demanding conditions; the grass is cut, dropped to the ground by the action of the wheels allowing easier control when moving forwards. The cutter bar’s teeth are have a special profile for a perfect cut and are made of special heat treated steel. The blade tensioners are adjustable ensuring constant contact between blade and teeth. |

|

|

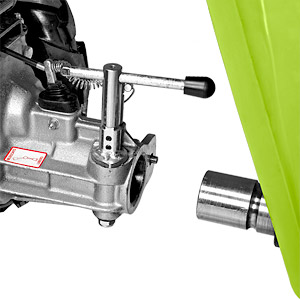

The GF2’s quick coupling allows the change of implements without ever unscrewing any nut. By operating a practical lever you unlock the quick coupling mechanism allowing you to replace other implements. It’s an easy-to-do procedure that you can do without any efforts. |

| The GF 2’s weight distribution was designed to ensure stability when mowing on slopes. To further increase the stability on slopes you have the possibility to increase the track by up to 24 cm with the wheels extensions. The agricultural profile tyres ensure high grip and the handlebar can be adjusted laterally. |

|

|

The GF2’ mechanic transmission with its gears in an oil bath are located inside the carter made of pressed aluminium. The lever operated gears and P.T.O. are easily reachable. |

|

The GF2’s gearbox has 3 forward and 3 reverse gears is designed to obtain the optimum speeds for mowing, i.e. 1.0, 2.0 and 3.0 km/h, when fitted with the “Tractor” wheels 4.00-8. For a level cut, the cutter bar has to be free to incline adapting itself to the ground’s unevenness. The handlebar was mounted on vibration-proof elements which dampen the vibrations also laterally. The handlebar is laterally adjustable in order to work more easily on slopes and can be adjusted in height in order to meet the user’s requirements. Furthermore it is reversible and can be lowered to considerably reduce the machine’s size. All controls are in a comfortable position, including the handlebar’s adjustment levers. |

|

|

The GF2 is fitted with either a Loncin G200FA petrol engine or with the Honda GX200 OHV petrol engine; both models have recoil start and are fitted with the latest technological innovations ensuring easy starting, reliability, low emissions, reduced consumptions, high performance and vibrations which are reduced to the minimum. Grillo GF2 engines are fitted with rear bumper. |

| Grillo have implements available to enhance the GF2’s usefulness, such as a 50 cm rotary cutter with blade brake and, for winter, a 100 cm orientable snow blade as well as a 80 cm orientable and tilting sweeper. |

|

|

The GF2, as all products by Grillo, was projected and built to last and keep its value for many years. |

|

Painting of Grillo machines consists of a double electrostatic powder coated process. At the beginning there are the washing baths and the preparation, then a first protective coat is applied together with the baking in the oven, turns out to be the best basis for the application of the finishing. The second coat consisting of varnish and a further baking in the oven at 190°C convey the characteristic hardness and brilliance. All GF2 have been mounted with care for every detail and tested scrupulously by specialised personnel. Final inspection means also machine with started-up engine in order to check the functionality. This is a further and final guarantee for a high quality product. |

|

| All Grillo products are distributed and serviced by a widespread Grillo specialist dealer net. Spare parts remain available also after a lot of years. |

|

Engine |

Honda GX200 OHV Start recoil starter Supply fuel Displacement 196 cc, 1 Cylinder Power 5.5 HP (4.1 kW) Air cooled Oil bath air filter |

| Engine |

Loncin G200FA Start recoil starter Supply fuel Displacement 196 cc, 1 Cylinder Power 5.5 HP (4.1 kW) Air cooled Oil bath air filter |

|

|

Fuel tank capacity | 3 L eng. G200FA - 3,1 L eng. GX200 |

|

Transmission | with oil bath gears |

| Gearbox | 3 forward gears + 3 reverse gears | |

| Clutch | conic active | |

|

Standard cutter bar | Single-blade PRO cutter bar 117 cm with crank action, p/n 9M6811 9M7511 |

| P.T.O. | 965 rpm anticlockwise rotation | |

|

Available tyres | Pneumatic wheels tractor 4.00-8 (fixed disks) and 16x6.50-8 (fixed disks) |

| Handlebar | height and side adjustment. Fitted on anti-vibration blocks | |

| Safety devices | Active conic clutch according to law | |

|

Weight | Weight: standard version 96 kg (with GX200); 98 kg (with G200FA) |

Pneumatic tractor wheels 4.00-8 (fixed disks with two positions); pair

to be applied on G 107d - G 55 - G 84 - G 85d - GF 2 - GF 3 - GF 3DF - MAX1 - WR77 PRO - WR78 PRO

item no.: 900112

weight: 9 kg

Pneumatic wheels 16x6.50-8 (fixed disks) (Pair)

to be applied on G 55 - GF 2

item no.: 912712

weight: 14 kg

Single-blade PRO cutter bar 117 cm with crank action

to be applied on G 55 - GF 2

item no.: 9M6811 9M7511

weight: 36 kg

Middle cut fingers central cutter bar 110 with crank action

to be applied on G 55 - GF 2

item no.: 9M7211 9M7511

weight: 39 kg

Double blade central cutter bar 117 cm with action

to be applied on G 55 - GF 2

item no.: 9L2811

weight: 45 kg

Cutter bar side protections for item 9L2811 and item 9L6911

to be applied on G 55 - GF 2

item no.: 9C0112

weight: 1,5 kg

Side protections for cutter bar p/n 9L2811 and 9L6911

Wheel extensions 12 cm (pair) (fit 2 pairs max)

to be applied on G 107d - G 108 - G 110 - G 131 - G131 BC - G 55 - G 85d - GF 2 - GF 3 - GF 3DF

item no.: 937112

weight: 2 kg

Weight for front blade

to be applied on Dumper 507 - G 107d - G 108 - G 110 - G 131 - G131 BC - G 52 - G 55 - G 85d - GF 1 - GF 2 - GF 3 - GF 3DF - GH 7 - GH 8 - GH 9

item no.: 9E6111

weight: 20 kg

Rubber end for blade 100 cm

to be applied on G 55 - GF 2 - GH 7 - GH 8 - GH 9

item no.: 9E5911B

weight: 1 kg

Snow chains for 4.00-8 wheels (pair)

to be applied on G 55 - GF 2 - GH 7 - GH 8 - GH 9

item no.: 9M3422

weight: 2 kg

Snow chains for rear wheels 16x6.50-8 Climber 7 series (pair)

to be applied on Climber 7.15 - Climber 7.18 - G 55 - GF 2 - GH 7 - GH 8 - GH 9

item no.: 9M3722

weight: 2 kg

Full Range Catalogue 2024

(Download - file pdf - 21,78 MB)

Full Range Catalogue 2024

(Download - file pdf - 21,78 MB)

PRO CUTTING BAR_Catalogue

(Download - file pdf - 184,21 KB)

PRO CUTTING BAR_Catalogue

(Download - file pdf - 184,21 KB)

![Pair pneumatic "Tractor" wheels 4.00-8 [fixed discs] - COD. 900112 Pair pneumatic "Tractor" wheels 4.00-8 [fixed discs] - COD. 900112](/data/thumb_cache/_data_img_prodotti_A636_jpg_rw_200.jpg)

![Pair pneumatic "Tractor" wheels 16X6.50-8 [fixed discs] - COD. 912712 Pair pneumatic "Tractor" wheels 16X6.50-8 [fixed discs] - COD. 912712](/data/thumb_cache/_data_img_prodotti_A637_jpg_rw_200.jpg)